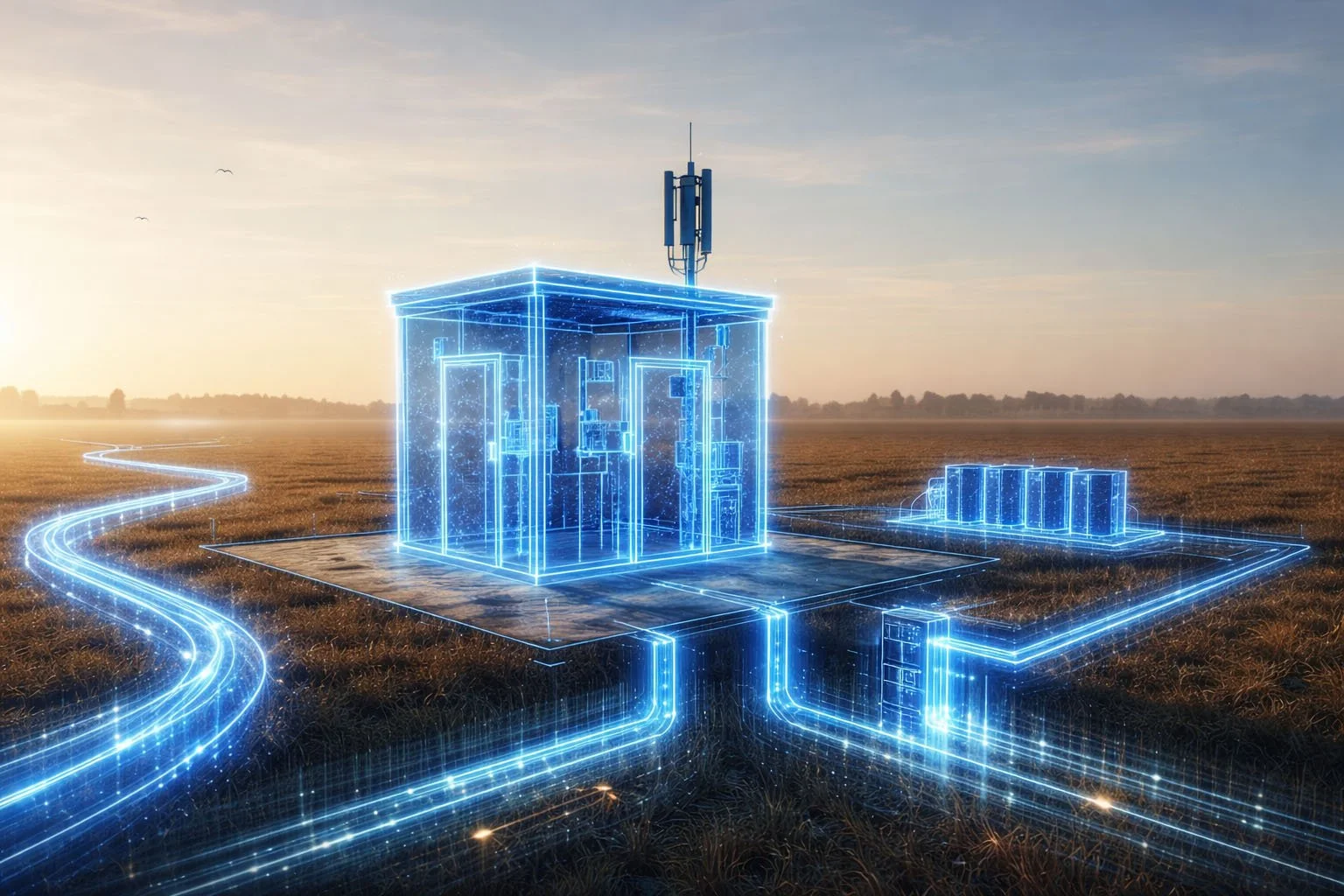

The unseen systems

that keep long-haul

networks

alive

infrastructure

Behind every high-capacity fiber route is a layer of infrastructure designed to be invisible, resilient, and relentless. In-Line Amplifier (ILA) huts don’t terminate traffic or process data—they exist to quietly preserve optical signals, keep power flowing, and protect physical assets across vast distances. Fiber, DC power, and racking work together as a single system; if any one fails, the entire route is at risk.

Fiber

The continuous optical path

Fiber is the reason the ILA hut exists. It is the uninterrupted optical medium that carries massive volumes of data across hundreds or thousands of kilometers, while the hut protects, splices, monitors, and amplifies that signal without ever converting it back to electricity. Every design decision inside the hut is ultimately made in service of preserving fiber quality and signal integrity.

In long-haul networks, fiber spans are carefully engineered to balance distance, attenuation, and noise. ILA huts are placed precisely where optical power needs to be restored, allowing signals to remain optical end-to-end. This approach minimizes latency, reduces cost, and enables ultra-long-haul and high-capacity routes.

As traffic demands grow—especially with AI workloads—the fiber itself becomes the limiting factor. Loss, reflections, and OSNR margins all determine how many wavelengths and how much capacity a route can support, making fiber quality and management more critical than ever.

Key roles of fiber in an ILA hut:

Carries DWDM signals across long distances without regeneration

Defines span length, amplifier gain, and noise budgets

Enables remote monitoring via optical supervisory channels

Supports redundancy through diverse working and protect paths

Determines long-term scalability for higher speeds and modulation

DC Plant

Power that the network can trust

The DC plant is the single most critical reliability system in an ILA hut. Optical amplifiers are always-on devices—if DC power is lost, amplification stops instantly and every wavelength on the route drops. No amount of fiber quality or optical sophistication can compensate for a power failure.

To prevent this, the DC plant isolates sensitive optical equipment from unstable utility power. Rectifiers convert incoming AC into clean –48V DC, while batteries provide immediate ride-through during outages, storms, or prolonged grid failures. In many remote locations, the battery system is the only thing keeping the route alive.

As networks scale for higher optical power and denser wavelengths, DC plants must also evolve. Modern AI-era optics demand more power, tighter voltage stability, and better monitoring—pushing older DC designs to their limits and driving infrastructure upgrades.

Key functions of the DC plant:

Converts unstable utility power into clean, carrier-grade –48V DC

Provides uninterrupted operation during outages via battery backup

Protects optical performance by minimizing voltage ripple and noise

Enables unattended, remote operation with full alarm visibility

Prevents cascading failures across adjacent huts and spans

Racking & Connectivity

The physical foundation of reliability

Racking may look like simple furniture, but in an ILA hut it is mission-critical infrastructure. Racks provide the structural integrity that keeps fiber, power, and optical equipment aligned, cooled, and protected—often in remote, harsh environments where human access is limited.

Proper racking prevents many of the most common causes of ILA outages: accidental fiber damage, airflow blockages, unstable power connections, and human error during maintenance. Well-designed racks enforce bend radius, manage slack, separate power from fiber, and maintain safe working clearances.

Racking also determines how easily a hut can scale. Space for additional shelves, higher-density amplifiers, and future equipment upgrades allows networks to evolve without rebuilding the site—a critical advantage as traffic and power demands increase.

Why racking matters in an ILA hut:

Protects fiber from micro-bends, strain, and accidental damage

Ensures proper airflow and thermal stability for optical equipment

Safely organizes high-current –48V DC power distribution

Enables fast, low-risk maintenance on live traffic

Supports future expansion without service disruption